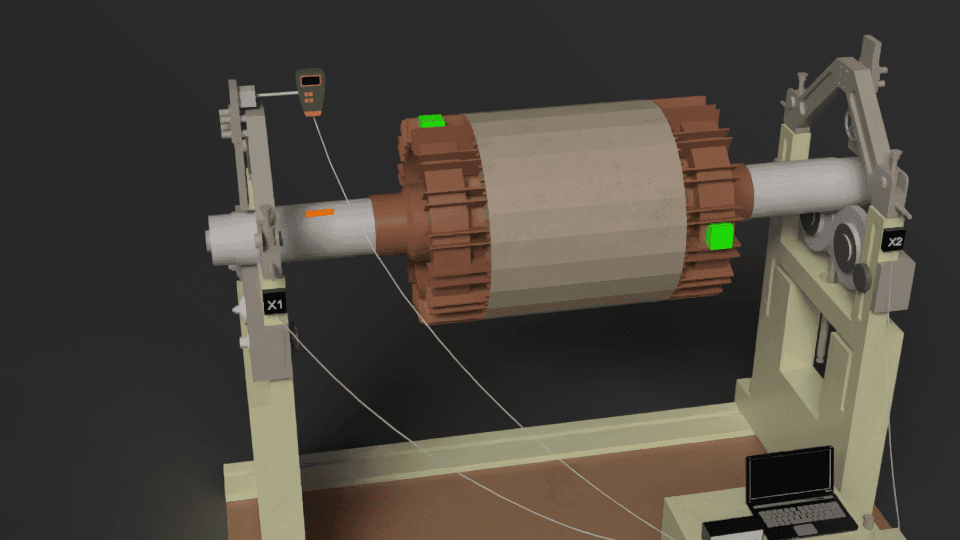

Detailed Rotor Balancing Process

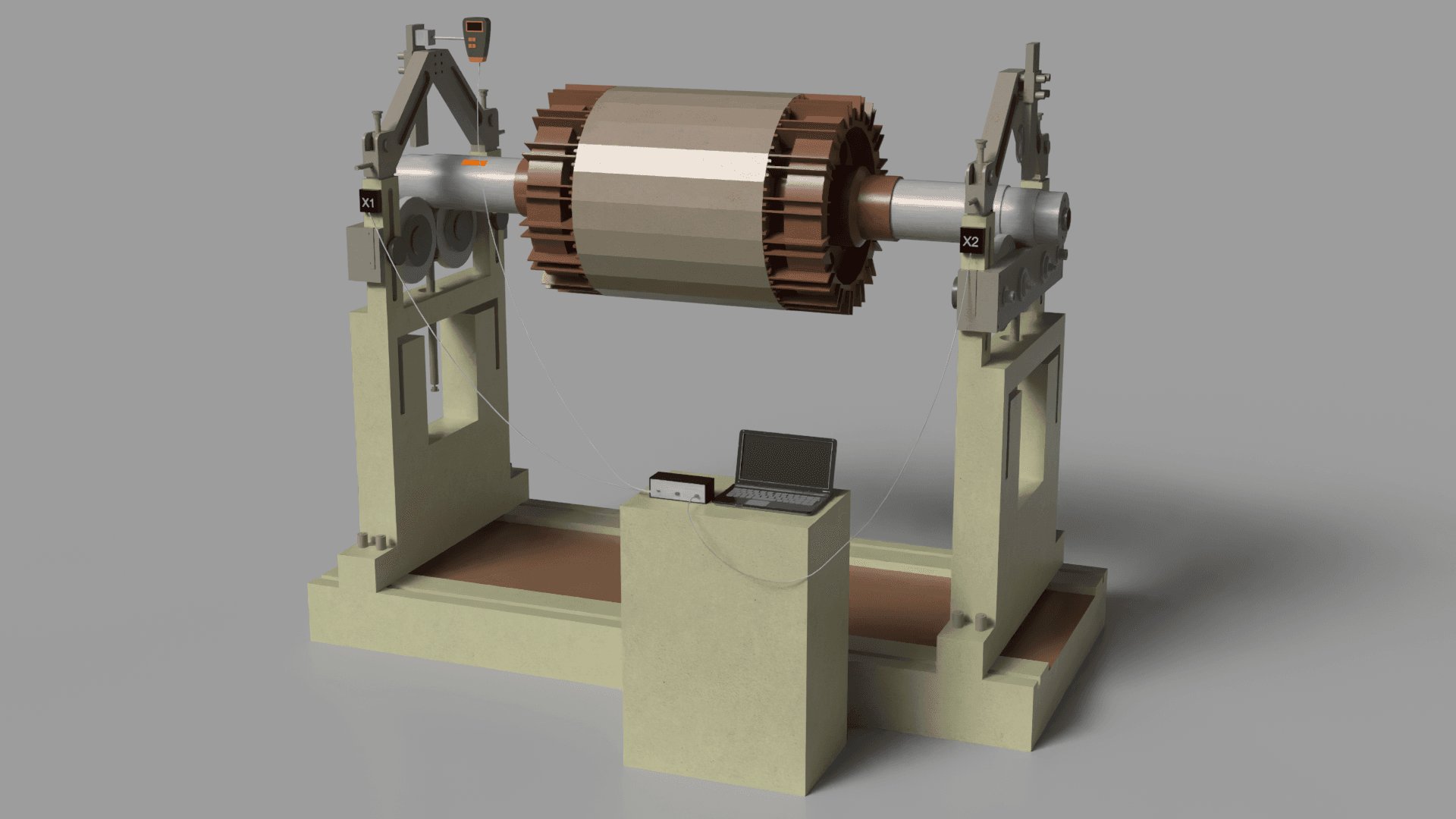

Equipment Preparation

- accelerometers, laser rpm sensor, mounting stand, software application, and additional tools.

- Connect the device to your PC using the USB interface and confirm the software installation.

Mounting the Sensors

- Attach the vibration sensors firmly to the machine casing in areas with the highest vibration amplitude, usually close to the bearing supports.

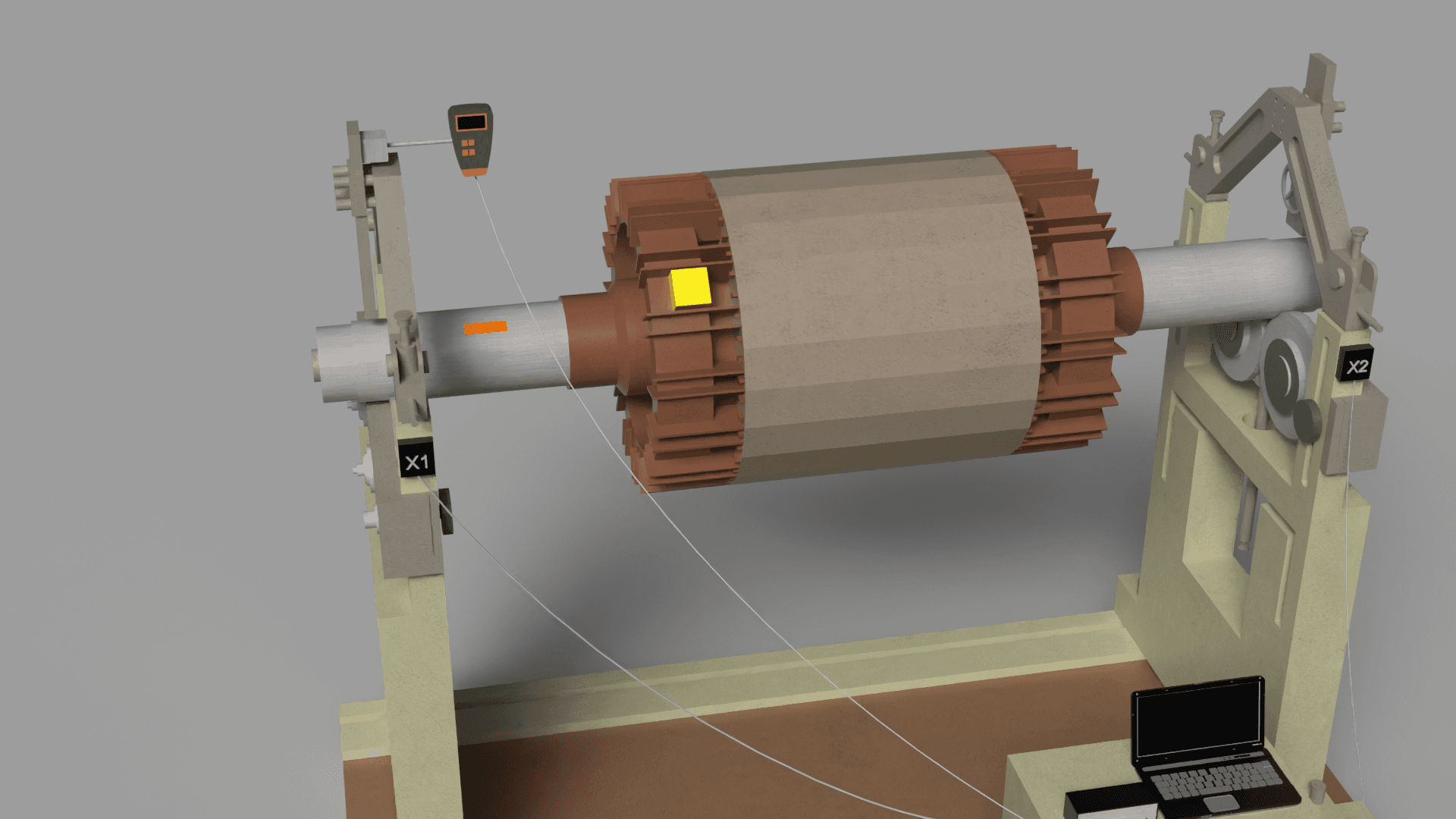

- Direct the laser speed sensor towards the rotor and affix reflective tape to the rotor surface to facilitate phase angle measurement.

Launching the Software

- Open the Balanset application on your PC.

- Select the appropriate balancing mode: single-plane or two-plane, depending on the rotor type and your specific requirements.

Measuring Initial Vibration

- Run the rotor up to its operating speed.

- The software will measure the vibration level, rotational speed, and phase angle. This data establishes the current imbalance condition.

Mounting the Test Weight

- Halt the rotation and mount a test weight at a designated position on the rotor, with the weight's value entered into the software (usually in grams).

- Resume rotor operation, and the program will capture the resulting changes in vibration amplitude and phase.

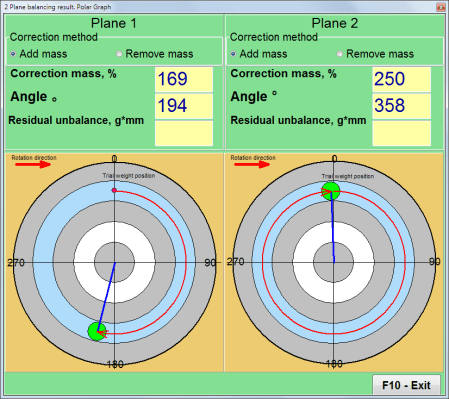

Calculating the Correction Weight

- Based on the measured data, the software automatically calculates the correction weight parameters: mass and installation angle.

- The calculated values are presented on-screen in both numerical and graphical formats.

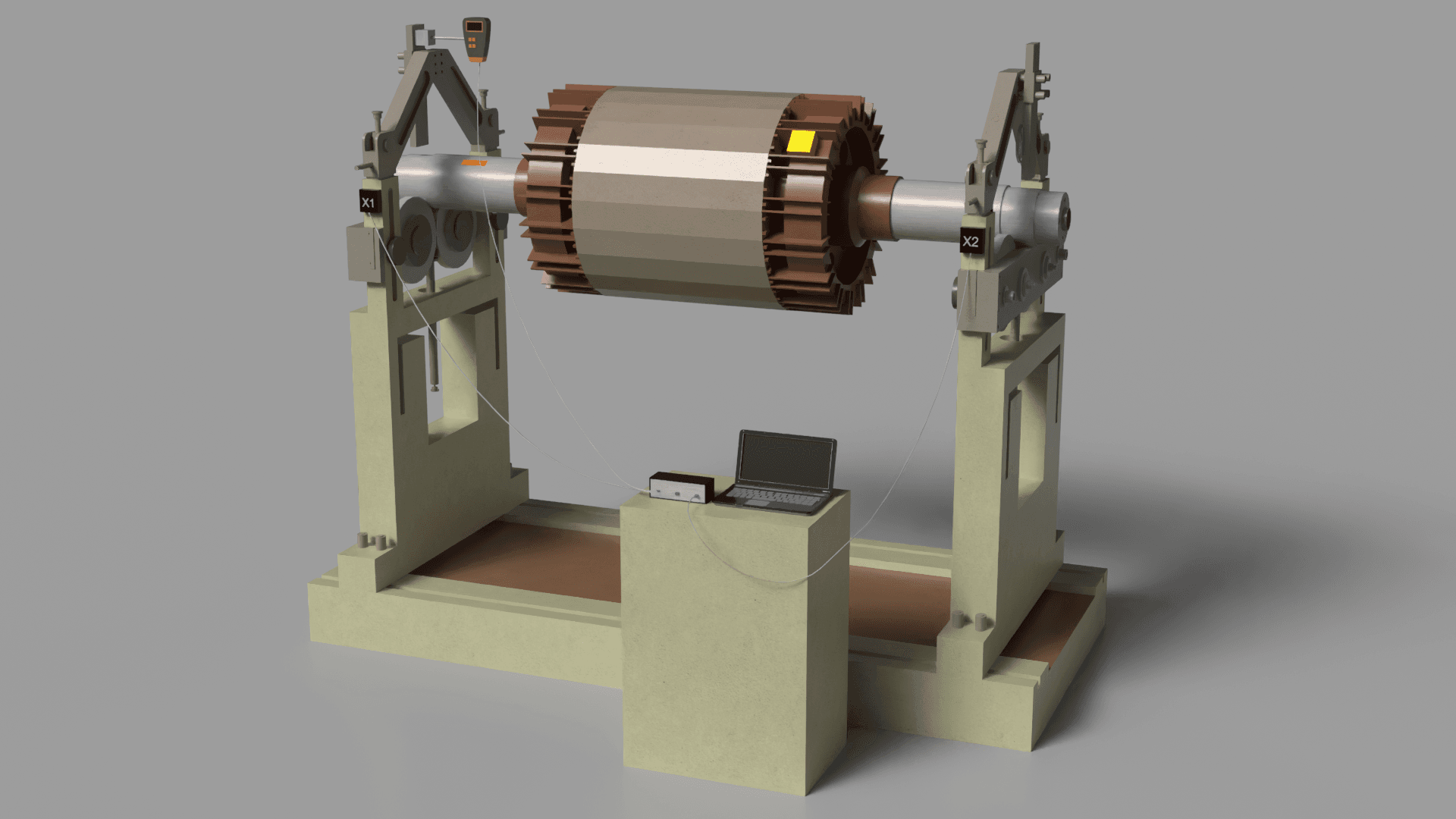

Installing the Correction Weight

- Install the correction weight on the rotor according to the software's calculations.

- If necessary, perform intermediate checks to verify that the imbalance is being reduced.

Verification and Balancing Completion

- After installing the correction weight, run the rotor again and check the residual vibration level.

- If the measured vibration falls within the tolerance defined by ISO 1940, the balancing process is considered successful.

- If the vibration is still outside acceptable limits, reiterate the process and fine-tune the compensating weight.

Report Generation

- The program stores the balancing data, allowing you to generate and print a comprehensive report including vibration measurements, corrective weight details, and its angular placement.

Post-Balancing Checklist

- Ensure all applied weights and attached sensors are firmly fixed in their designated positions.

- Confirm that the rotor spins freely and quietly, without any unusual sounds or vibrations.

- If the rotor is part of a complex mechanism, verify the proper interaction of all its components.

Instagram: https://www.instagram.com/vibromera_ou/

Youtube : https://youtu.be/guA6XJ-ArZM?si=vmkuX7RILzKBl0zL

Our website about Field balancing

Machinio: https://www.machinio.com/listings/98380186-portable-balancer-vibration-analyzer-balanset-1a-full-kit-in-portugal

Facebook: https://www.facebook.com/marketplace/item/350151228150722

Доброго!

Долго обмозговывал как поднять сайт и свои проекты и нарастить ИКС Яндекса и узнал от крутых seo,

отличных ребят, именно они разработали недорогой и главное буст прогон Xrumer - https://www.bing.com/search?q=bullet+%D0%BF%D1%80%D0%BE%D0%B3%D0%BE%D0%BD

Xrumer для создания ссылочной стратегии помогает системно подходить к линкбилдингу. Программа размещает ссылки на форумах и блогах. Массовый прогон ускоряет рост DR. Чем больше качественных ссылок, тем выше позиции сайта. Xrumer для создания ссылочной стратегии – эффективный метод SEO.

самуэль сео, обучение созданию и продвижению сайтов бесплатно, SEO рассылки форумов

линкбилдинг что это такое, services seo, как seo оптимизировать тексты

!!Удачи и роста в топах!!

Привет всем!

Долго обмозговывал как встать в топ поисковиков и узнал от друзей профессионалов,

отличных ребят, именно они разработали недорогой и главное top прогон Xrumer - https://www.bing.com/search?q=%D1%82%D0%B0%D1%80%D0%B8%D1%84+bullet+%D0%BF%D1%80%D0%BE%D0%B3%D0%BE%D0%BD+%D1%85%D1%80%D1%83%D0%BC%D0%B5%D1%80%D0%BE%D0%BC

Xrumer для создания ссылочной стратегии помогает системно подходить к линкбилдингу. Программа размещает ссылки на форумах и блогах. Массовый прогон ускоряет рост DR. Чем больше качественных ссылок, тем выше позиции сайта. Xrumer для создания ссылочной стратегии – эффективный метод SEO.

методы сео, seo образец, Создание ссылок автоматическими прогами

Автоматическое размещение ссылок, советы по продвижения сайта, нужно продвижение сайта зачем нужно

!!Удачи и роста в топах!!

https://kozas.site